|

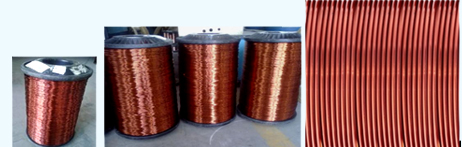

Application of Enamelled Aluminium Wire & Enamelled

Copper Wire

Enamelled Aluminium Wire or Enameled

Copper Wire is a wire coated with a thin layer of enamel

(varnish) insulation to prevent the wire surfaces from being

in a short circuit when wound into coils. Magnetic flux is

created when current flows through the coil. Aluminum Enameled

Wire and Copper Enamelled Winding Wire are used mainly in the

construction of motors, electromagnets, transformers and

inductors. For ease of manufacturing inductive components like

transformers and inductors, most of these wires can be

soldered.

Enameled Aluminum Wire or Enamelled

copper wire, also called "Magnet Wire," is widely used in

various Electrical Applications due to its superior

Electrical, Thermal and Mechanical Properties. Enameled

Aluminium Wire /Enameled Copper Wire are insulated by coating

it with enamel of different temperature class. Enamelled

Aluminum Wire /Enamelled Copper Wire are primarily used in

three types of applications - in transformers to transform one

kind of electrical energy into other kinds. Aluminum Enameled

Wire and Copper Enameled Winding Wire are used in motors to

transform electrical energy into mechanical energy. Enamelled

Aluminium Winding Wire /Enamelled Copper Winding Wire are also

used in generators to transform mechanical energy into

electrical energy.

Enameled Aluminum Magnet Wire and

Enamelled Copper Magnet wire are used as the wire in

electromagnets that use electricity to generate a magnetic

field. Enameled Rectangular or Flat Aluminium Wire and

Enameled Rectangular or Flat Copper Wire /Strip is wrapped in

a tight coil. When an electric charge is applied, the wires

generate the magnetic field. Flat Enamelled Aluminium Wire and

Flat Enamelled copper wire have a wide variety of

applications, including use in automobiles, motors,

transformers and industrial machineries. Round Enameled

Aluminium Wire and Round Enameled copper wire are also found

in smaller devices and home appliances, such as computers,

televisions etc.

Like other wire, Aluminium & Copper

Enamel Magnet Wire is classified by diameter (AWG number or

SWG) or area (square mili meters), temperature class, and

insulation class.

Breakdown voltage of Aluminium Enamelled

Winding Wire or Copper Enamelled Winding Wire depends on the

thickness of the covering, which can be of 3 types: Grade 1,

Grade 2 and Grade 3. Higher grades have thicker insulation and

thus higher breakdown voltages.

The temperature class indicates the

temperature of the wire where it has a 20,000 hour service

life. At lower temperatures the service life of the wire is

longer (about a factor 2 for every 10 °C lower temperature).

Common temperature classes are 105° C, 130° C, 155° C, 180° C

and 220° C.

Advantage of Enamelled Aluminium

/Enamelled Copper Round & Flat Winding Wire

Size

One of the

primary properties that make Enamelled Aluminium Wire and

Enamelled copper wire desirable for wide applications is the

thin enameling insulation. Transformers, motors and

generators are all machines based on the coil, which is a

device that generates magnetic fields and electrical

currents using large coils of wire. The smaller these

devices are, the stronger they are. Because Enameled

Aluminum Magnet Wire and Enameled copper Magnet Wire is

insulated by a thin coat of enamel instead other types of

thicker insulation like paper, fibre glass, mica etc. As

Enamel Aluminum Wire or Enamel Copper Wire takes up less

space in coil formation so it makes more effective and

compact coils with higher

efficiency.

Conductivity

Enameled

Aluminium Winding Wire and Enameled copper Winding wire are

widely used in electric devices because of their

conductivity. Aluminium Enameled Wire and Copper Enameled

wire are meant to carry electrical currents. Specially,

Enamel Copper Magnet Wire has less resistance than almost

any other insulated wires. This means that generators using

enamel copper wires will produce more electricity than

generators using most other substances. Coils of Motors made

of Enamel Copper Winding Wire will produce more motion.

Transformers made of Enamel Aluminium Wire or Enamel Copper

Wire will lose less energy.

Resistance to

Corrosion

The third

feature of enameled copper wire / enamelled aluminum wire

that make them so attractive for use in these devices is its

resistance to corrosion. Enamelled Aluminum & Copper

Magnet Wire is the material of choice for use in electrical

circuits, as it lasts for a long

time.

The mechanical, electrical and chemical

characteristics of enamelled aluminum magnet wire differ from

those of copper magnet wire because of the inherent

differences in the conductor materials. These differences are

reflected in certain test procedures and/or performance

requirements for aluminum enameled magnet wire, such as

elongation, adherence and flexibility, heat shock, scrape

resistance, continuity and thermal

endurance.

The advantage of aluminum enameled

winding wire is light weight. This product is widely used in

electrical tools, ballasts, automotive electronics,

refrigerator and air conditioner compressor motors, television

sets, electric stove, microwave ovens, various transformers,

and other kinds of electronic coil motors, electrical

appliances.

Enamelled Aluminium magnet wire is

sometimes used for large transformers and motors, but because

of its lower electrical conductivity, an aluminium enameled

wire must have 1.6 times the cross sectional area as a copper

wire to achieve comparable DC resistance. Smaller diameter

magnet wire usually has a round cross section. Thicker

Aluminum Magnet Wire is often square or rectangular (with

rounded corners) to permit more efficient use of available

winding space.

Modern Enamelled Aluminium Magnet Wire or

Enameled Copper Magnet Wire typically uses one to three layers

of polymer film insulation, often of two different

compositions, to provide a tough, continuous insulating layer.

Magnet wire insulating films use (in order of increasing

temperature range) polyvinyl formal or Formvar (PVF),

polyurethane, polyamide (PUW), polyester (PEW),

polyester-polyimide (EIW), polyamide-polyimide (or

amide-imide) (AI-EIW), and polyimide (AIW). Polyimide

insulated magnet wire is capable of operation at up to 250°C.

The insulation of thicker square or enamelled rectangular

aluminium or copper magnet wire is often augmented by wrapping

it with a high-temperature polyimide or fiberglass tape, and

completed windings are often vacuum impregnated with an

insulating varnish to improve insulation strength and

long-term reliability of the winding.

Other types of insulated conductors

such as fiber glass insulated copper / aluminium round &

flat wires with varnish, nomex insulated copper / aluminium

round & flat wires, kraft paper insulated copper /

aluminium round & flat wires, mica insulated copper /

aluminium round & flat wires, kapton insulated copper /

aluminium round & flat wires, and polyester film insulated

copper / aluminium round & flat wires are also widely used

across the world for various applications like motors,

transformers and reactors.

Various Applications of

Enamelled Aluminium Wire & Copper Enamelled

Wire

Dual Coated Enamelled Aluminium Wires

/Copper Wires are suitable for all "H + " (220°C and

200°C) Class and above applications such as dry type

transformers, stator winding fractional and integral H.P

motors, D.C Field and Armature windings, Motors for Hermetic

grade, Hand tools, Chemicals Industries, Furnaces and high

Torque, continuous rated, all Home appliances machine motors,

Auto electrical, coil application-varnished or unvarnished.

Enameled Aluminum Wire

or Enameled Copper Wire of Hermetic Grade has Excellent suitability

for refrigeration and air conditioning

systems.

Single Coated Wires

are suitable for all "H","F" and "B"

Class application such as dry type transformers, stator

winding fractional H.P. motors, D.C field and Armature

windings. Polyester coated wires have very good chemical

resistance and compatible with all general purpose

impregnating varnishes including high temperature modified

phenolic polyester and others which do not contain the

reactive solvent.

|

All

our products are manufactured as per

International Standards and Specifications given

by the customer .We offer a selection of

dimensions, types of covering and materials

for special fields of application.

All

our products are manufactured as per

International Standards and Specifications given

by the customer .We offer a selection of

dimensions, types of covering and materials

for special fields of application.